- Friendly HMI with easy switch for multi-languages.

- Advanced reflection system by ceramic plate, heat-preservation system and heating system, preform can be heated evenly.

- Unique high-pressure gas recovery system that saves more than 30% of compressed air.

- Ionized de-duster can be equipped to improve the cleanliness of the packaging container.

- The tailored made servo stretching system can be adapted to preforms with various stretching ratio, achieving the variable speeds and high accuracy positioning.

- The filling valve is designed with the tidy and safe valve body, the material quality can be fully guaranteed.

Description

Newamstar’s bottled water packaging solution includes one-stop solutions from water treatment to palletizing systems and intelligent logistics. Newamstar’s bottled water packaging solutions are widely used in world-renowned beverage factories. Newamstar’s bottled water packaging solutions are suitable for the integrated production of drinking water, mineral water, purified water, mountain spring water, soda water, salt soda and other products.

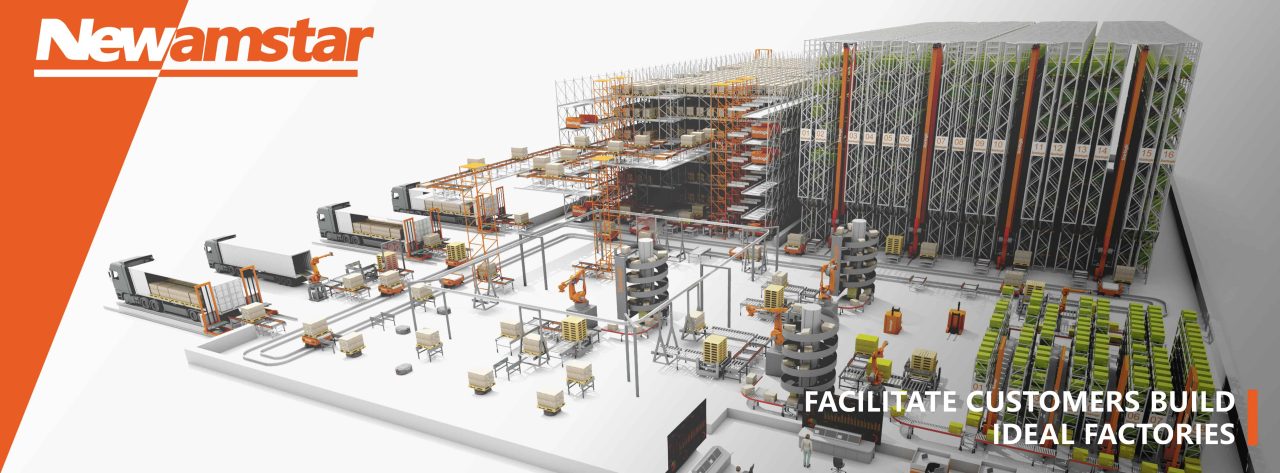

Newamstar can provide users with planning, designing and implementation ofsmart factory integration projects. From product recipe, three-dimensional bottledesign to factory overall planning,and from key equipment R&D,softwareplatform customization & development to full life cycle service of engineeringprojects, we keep pace with the times, pioneer and innovate, and realize thedream of “Made in China, Made for World”.

- Applicable Products: Pure Water, Mineral Water, Spring Water, Etc.

- Suitable Container: PET bottles of various shapes and capacities

- Filling Modes: Mechanical valve filling, flow meter filling, weighing filling or laser positioning filling

- Capacity Range: 12,000 bottles/hour – 81,000 bottles/hour (500 ml) for the 150ml – 1,500ml bottle

1. Whole-Plant Project

With high-quality equipment, perfect service, and strong turn-key service capabilities, Newamstar helps customers achieve a high-efficiency operation of equipment and technical innovation and upgrade to join hands with customers for a win-win situation.

2.After-Sales Support

With the expansion of the global market, Newamstar will, relying on six domestic and overseas service centers, provide technical support and after-sales services to customers all over the world to protect the development of customers’ business.

3.Spare Parts

Taking full consideration of customers’ actual situation and needs, Newamstar will ensure the stable operation of their equipment according to the operation of the customers’ factory and provide spare parts support for them in time.

Greater customer benefits

Running production tasks shall require significantly less time and effort, allowing customers to focus entirely on their core business.

Greater flexibility

Customers shall be in a position to increase their adaptability and react flexibly to changes in the market or in their business models.

Greater profitability

System performance shall be adapted to the required availability, thus increasing profitability by minimizing staffing, reducing wear, and decreasing energy consumption.

We can help you capitalize on today’s innovative technologies to become more agile, respond effectively to change, improving the entire line of production efficiency, reducing investment costs, energy consumption and maintenance costs, and position your business for a successful future.

From the filling method and output, through to the level of hygiene: Newamstar specialists will be only too pleased to provide you with advice on the best system to use in your bottling line.

WhatsApp: +86 18521300509

E-Mail: e@newamstar.com

Web: http://en.newamstar.com/

Linkedin: https://www.linkedin.com/company/newamstarchina/

Facebook: https://www.facebook.com/newamstarchina/